Brass Moulding Inserts

With firm responsibility to quality, our firm is occupied with offering a far-reaching scope of Brass Moulding Inserts to our valuable customers. Customers can profit from these stainless steel embed from us in different measurements, evaluations, and gauges according to their prerequisites. Further, we guarantee to convey the committals at supporters’ destination inside of the guaranteed period.

We are specialized in the manufacturing of Brass Cross Knurled Inserts, Brass Moulding Inserts, Aluminium Moulding Inserts, Stainless Steel Moulding Inserts available in a variety of designs, shapes, and sizes mainly exporting to international markets to maintain high-quality standard and flawless properties.

Insert molding metal inserts are derived directly from insert injection materials and are regularly used in a wide range of industries including: aerospace, medical, defense, electronics, industrial and consumer markets. The applications for metal inserts for plastic parts, include: Screws. Studs.

It is useful in metal to plastic conversion to make parts more efficient. There is increasing demand across industries to produce parts in plastic instead of metal — to lower weight, reduce production costs, and eliminate corrosion. Insert molding allows retention of essential metal elements within a plastic part.

Brass Moulding Inserts are precision-machined threaded metal inserts designed to be embedded directly into plastic components during the molding process. These inserts provide strong, durable, and reusable threads in plastic parts, enabling secure fastening and repeated assembly without thread wear or failure.

Manufactured from high-quality brass alloys, moulding inserts ensure excellent mechanical strength, corrosion resistance, and long service life, making them ideal for injection-molded plastic products used across multiple industries.

Benefits – Brass Moulding Inserts

- Reduced post – moulding operations: If the insert is moulded properly , it provides strength and shape to the Moulding and greatly decreases the post-molding operation. This helps in reducing costs in assembly and reduces the requirement for labor, which automatically makes it available for further production quicker and faster.

- Increased part consistency: When we talk about consistency, the insert helps in increasing it to a very large extent. Since they make use of the same kind of Moulding and exactly the same machinery and technology, they are an exact replica of each other, which is very good for the production process.

- Ease of assembly: one of the most important parts about using inserts is that they make assembly easier. It reduces efforts, which would have been necessary if different inserts had to be fitted separately and if they had to be done after the moulding stage. Since they are done altogether, they can all be clipped at the same time.

- Reduced production time: vertical moulding machines come with a rotary table, which helps reduce production time. They are fixed with various tools, both on the upper and lower parts. Therefore, the inserts and moulding are formed at the same time, which decreases the amount of work as well as the time taken. Not only does it reduce the production time and increase accuracy, but it also reduces the number of people needed to complete the production process.

Brass Moulding Inserts

Key Advantages

✔ Strong and wear-resistant metal threads

✔ Excellent resistance to corrosion and oxidation

✔ High pull-out and torque resistance

✔ Long-term reliability in plastic components

✔ Suitable for high-volume production

✔ Allows repeated assembly & disassembly

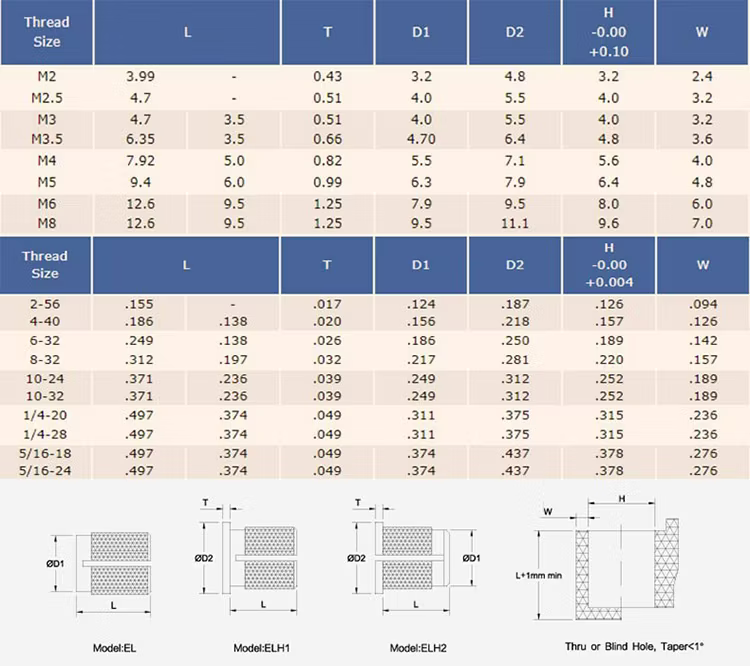

Specification of Brass Moulding Inserts

Material: Brass to BS 2874 / 2872

Finish: Brass natural, Electro-Tinned, Nickel etc.

Thread: Metric, BSW, BA, BSF, UNC, UNF UNEF etc.

Size: 2mm 3mm 4mm 5mm 6mm 8mm 10mm 12mm 16mm 20mm 25mm 32mm 1/8″ 5/32″ 3/16″ 1/4″ 5/16″ 3/8″ 1/2″ 5/8″ 3/4″ 1″ 11/8″ 11/4″ 11/2″ 13/4″ 2″

Material & Manufacturing

Material: High-grade Brass (Copper-Zinc Alloy)

Manufacturing Process:CNC machining, Automatic lathe turning & Hot forging (as per design)

Finish: Natural brass / Nickel plated / Tin plated (optional)

Thread Standards:Metric (M2 to M16) UNC / UNF BSP (as required)

Types of Brass Moulding Inserts

🔹 Straight Knurled Inserts Standard cylindrical shape with straight knurls

🔹 Diamond Knurled Inserts Cross-knurled pattern for superior grip

🔹 Flanged Inserts Integrated flange to prevent axial movement

🔹 Hexagonal Inserts Hex shape provides enhanced anti-rotation properties

🔹 Blind Inserts Closed at one end to prevent screw pass-through

🔹 Custom Inserts Manufactured as per drawings, samples, or specifications

Applications

Brass moulding inserts are widely used in:

- Injection-molded plastic components

- Electrical & electronic housings

- Automotive plastic parts

- Home appliances

- Industrial enclosures

- Switchgear and control panels

- Consumer goods and toys

- Medical and laboratory equipment

Quality & Standards

- Manufactured as per ISO / DIN / ASTM standards

- Dimensional inspection and thread gauging

- High precision and consistent quality

- RoHS-compliant materials (on request)

Keyword of Moulding Inserts

Brass Moulding Insert in Delhi, Brass Moulding Insert, Brass Moulding Inserts, Brass Inserts for Mouldings, Brass Inserts Manufacturers & Suppliers,Brass Inserts DBI, Brass Moulding Inserts Manufacturers, Asian Fasteners Brass Moulding Inserts, Brass Moulding Inserts best price in india, Manufacturer of Brass Inserts Plastic Moulding, Customized Brass Molding Insert from India, Brass Inserts Provides Enhanced Strength For Plastic, Top Brass Moulding Insert Manufacturers, Metal and Brass Moulding Inserts Manufacturers & Supplier, Brass Moulding Insert Manufacturer from Pune, Brass Inserts Brass Moulding Inserts, Brass Insert manufacturer in india