How to use Brass Inserts for Wood? In ultramodern artificial operations, brass threaded inserts are veritably important useful. They’re part of fasteners to assemble and disassemble colorful types of accoutrements . They’re veritably important useful for wood as well.

The part of brass inserts differs grounded on the type of material and fitting. These inserts come in several sizes and homestretches. They’re available in several designs. Since the inserts don’t beget damage to the element, they bring a high position of re-usability.

How are these inserts used for wood? Let’s understand the process of installation in detail.

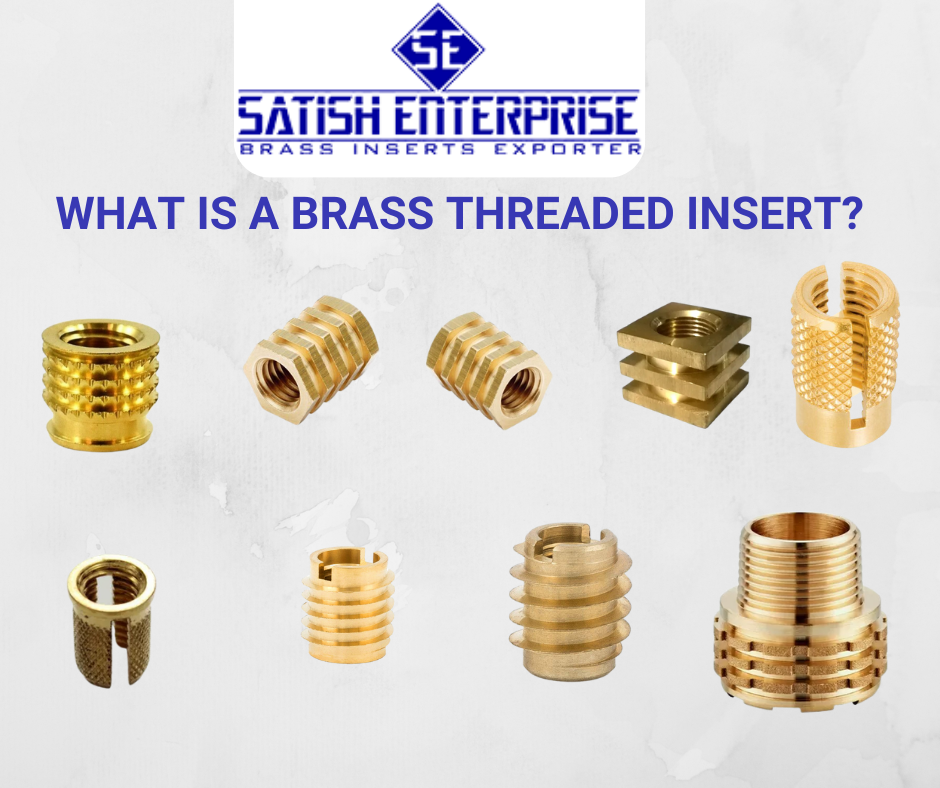

There are different types of inserts

The role of inserts differs based on the type of fittings and material. Brass inserts come in several types and the most commonly used inserts are:

- Male and female brass inserts

- Threaded and non-threaded inserts

- Polished and non-polished inserts

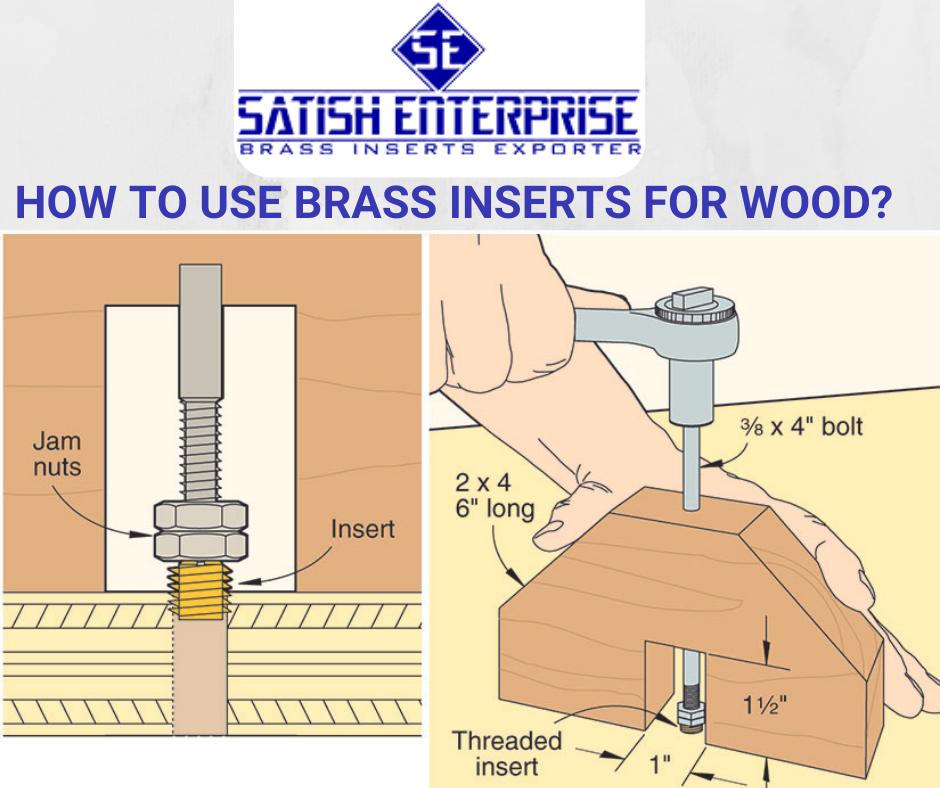

For wood- grounded operations, then’s the process of installing brass threaded inserts without using driving tools. It’s a step- by- step companion for the same. First, you need to drill a airman hole in the wood. It can be done by using an applicable drive tool. By reading the specification companion or primer of the insert, you can find the right size of the drill.

It’s also possible to use a Hex Cap Screw or Cap Bolt of the size of the insert. Now you should install the Hex Cap Screw in the brass threaded. The process is simple and can be done without any complex specialized knowledge. In the coming step, you need to place the assembly of Hex Cap Screw and fit it over the hole.

You need to use a wrench motorist for Hex Cap Screw and install the assembly in the hole. You’re supposed to flush the assembly with the wood to consider proper installation. This step is veritably important, and it has to be carried out with utmost care. Now, the Hex Cap Screw has to be removed by turning it in rear.

The palladium should be taken to remove only the cap screw and not the insert. You can strain it using a screwdriver if needed. It’s done to insure that the insert remains fixed in the wood. To get information about the installation process of brass inserts for wood, you can relate installation primer handed by the insert supplier.

It’s also possible to get information on the Internet. There are numerous service providers that are available on the web.